What Are Climbing Holds Made Of? (2024 Guide)

Published on: 01/13/2023

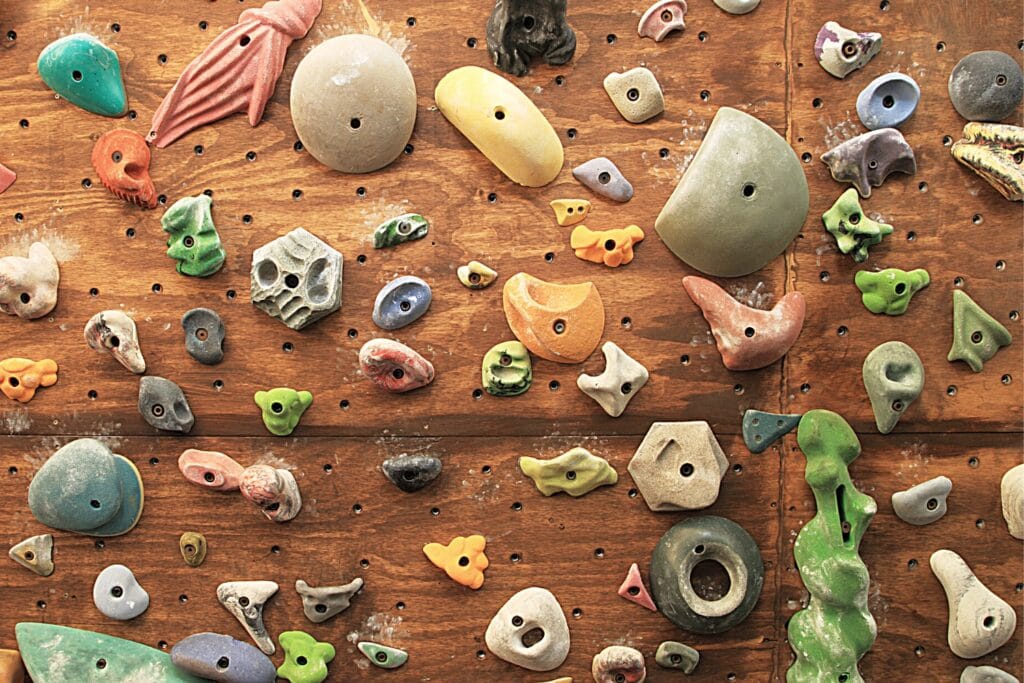

Most of us have spent a fair amount of time at indoor climbing walls. Some of the more DIY-oriented among us may even have our own climbing setup at home.

But for how often we grip artificial climbing holds, we don’t spend much time thinking about what they’re made of. That ends today.

We’re taking a look at how climbing holds are made.

What’s a Climbing Hold?

When outdoor climbing, we depend on natural materials forming into shapes we can gain purchase on with our hands and feet. Climbing gyms and other commercial facilities must use a variety of artificial holds that mimic the challenge of climbing on real rocks.

Gyms and Homemade Setups

Homemade climbing setups come in a variety of dirtbag levels. The simplest way to make a climbing wall is to build a frame with a 3/4-inch plywood sheet on top. Drilling holes in the sheet allows you to bolt the grips down from behind using t nuts.

You might also see a mix of homemade and commercially made climbing holds at a homemade wall. These can be made of wood, fiberglass, or polyurethane. Wooden holds are usually the cheapest to make at home but take the most time and effort. Wood holds don’t have the durability of their resin counterparts.

Commercial Gyms

The Climbing Wall Association publishes design and engineering specifications for indoor rock climbing walls in the US. Broadly speaking, there are four types of wall setups:

Panelized

These are common in smaller gyms. The factory makes wall sections and finishes with textured paint or resin. The sections are then assembled on-site.

Rock Realistic

Large custom sections of fiberglass-reinforced concrete are created to mimic real rock formations and then assembled on-site.

Seamless

The entire wall is built on-site and then coated with a layer of concrete for a seamless finish.

Types of Climbing Holds

Jugs

As the name suggests, jugs are larger holds that are typically easy to get a handle on. A jug is usually large enough to wrap most of your hand around.

Slopers

A sloper is a hold without any positive angle for you to wrap your fingers around. They are so-called because they slope away from the climbing wall and don’t have any edges to grip onto.

Crimps

A crimp is a climbing hold only large enough for the pads of your fingers. A full crimp means hard angles in your knuckles and your thumb tucked over the top for power. An open crimp means your fingertips are on the edge, but the rest of your hand hangs below—no hard angles on the knuckles.

Footholds

Everything on a climbing wall is potentially a foothold. But dedicated footholds are usually very small, creating only enough space for a toe or two.

Pockets

A pocket is a round hold bored into a grip to simulate the uneven surface of natural materials. They are often only large enough to place one or two fingers/toes into at a time.

Pinches

A pinch is a grip made up of two opposing edges. To maintain grip, climbers must pinch their thumb and fingers together.

Materials Used to Make Rock Climbing Holds

Polyester Resin and Polyurethane

A lot of the climbing hold industry in the USA prefers polyurethane nowadays. Polyurethane (1) is more flexible than polyester and less prone to chipping and snapping when mixed correctly.

However, quality polyurethane mixes are not as easy to achieve as those made with PE. If the PU mix is done incorrectly, the resulting resin may be too hard or too soft. This can lead to the PU splitting apart when the grip is tightened, the grip snapping, or the bolt pulling through the bolt hole.

Fiberglass and Resin

As the demand for larger volume commercial holds grew, the practicalities of making them from resin were tested. Resin holds are relatively heavy. To mitigate this, many poly holds are now made with a technique called hollow backing. This removes a lot of the internal material and reduces weight.

To do this, manufacturers use fiberglass. Fiberglass (2) has some tensile strength and helps the grip hold its shape and strength with less material. Companies are secretive about their hollow backing techniques. But we guess it’s a bit like making a paper mache balloon in 3rd grade.

Sand mixed in to the resin matrix can create texture in the finished holds. Different textures can also be applied to polyester and polyurethane grips after they’ve been molded.

Wood Holds

Low-tech but still great wooden climbing holds are still popular for DIY projects and online retailers. Any wood with a fine grain will work, but cherry and oak are probably best.

But making holds from wood is time-consuming and laborious. For this reason, commercially bought wooden rock climbing holds can be very expensive (and beautiful).

Rock

It is possible to drill holes through rocks and then fix them to a climbing wall with bolts. This is what climbers did in the early days of artificial climbing walls.

But there are problems with spinning and breaking. Natural rock is not flexible. If you overtighten the bolt, the rock will crack, and your hold is useless.

Rocks are also rarely perfectly flat on one side. This means that after some use they will loosen and begin to spin. Rubber backing can help with this, but rock is generally too heavy and finicky to be useful.

Manufacturing Process

Cut the Prototype

To make climbing holds, you need prototype shapes. Dense foam is an excellent material to create your prototypes because it’s textured and easy to work with. Cut rectangular/square pieces of foam into the different sizes you want.

The hole for climbing grips is countersunk, so the bolt is out of the way. Drill the small hole all the way through the center of the block first. Then drill the larger hole halfway through the material.

Now, carve the features you want into the foam block using a sharp knife. Soften any edges and further shape the block using sandpaper and pressure from your fingers and thumbs.

Prepare a Silicone bath

To create your mold. you’ll need some silicone and a container to sit your prototype in. You want a container that’s just large enough that the foam block doesn’t touch the walls. Some people (like the guy in the video linked below) glue their foam to a plastic backing and make plasticene dams around them.

When the foam is fixed to the bottom of your container (and you’ve checked nothing is touching the sides), it’s time to pour silicone. Many people do a two-part pour, allowing the first layer to partially cure before pouring the second. Tap the container often to knock out air bubbles.

Casting

Once the silicone has cured, remove the foam from the inside. You should be left with a sealed mold with a pillar in the middle representing the bolt hole. Drop a washer over this pillar. Clean up any rough edges on the mold and rinse.

Lay on a flat surface and pour in your activated resin until it reaches the lip of the mold. Once cured, the back of the hold will need to be sanded flat. The tiny air pockets in the foam are present as a texture on the surface of the resin.

For a more in-depth explanation, check out the video below from Climbing Workouts.

Main Companies

Some of the biggest names in the industry include Tekniks, Kilter, Atomik, and Flathold. Of these companies, Atomik is one of the most popular for a home setup. Decoy Holds, Metolius, KMZ, and Blue Pill are also popular brands at the moment.

Cost

Are you considering opening up a climbing gym or installing a wall to train at home?

A complete set costs about $200-300, depending on the holds you pick. Multiply that by the number of routes to set if you’re a prospective gym owner, and you can get a good picture of the investment required to launch such a business.

Sustainability and Durability

Sadly, casting resin holds is a toxic business (at least until the peanut and soy epoxies are ready). However, it’s important to factor durability into this discussion. A well-made polyester resin/PU resin hold could potentially last a lifetime.

Also, it’s likely that the commercial production of holds is more sustainable than many home projects. Companies carefully manage waste and (in theory) try to reduce their harmful impact on the environment. People messing around at home with toxic goo can be bad news.

References

Polyurethane, Wikipedia (retrieved on 01/13/2023)

https://en.wikipedia.org/wiki/Polyurethane

Fiberglass, Wikipedia (retrieved on 01/13/2023)

https://en.wikipedia.org/wiki/Fiberglass

This is literally the most inaccurate description of climbing holds I have ever read. The materials and manufacturing processes are completely misleading and I would suggest taking it off the web or at least doing some proper research with some hold companies.